Timing Belt Replacement Tip

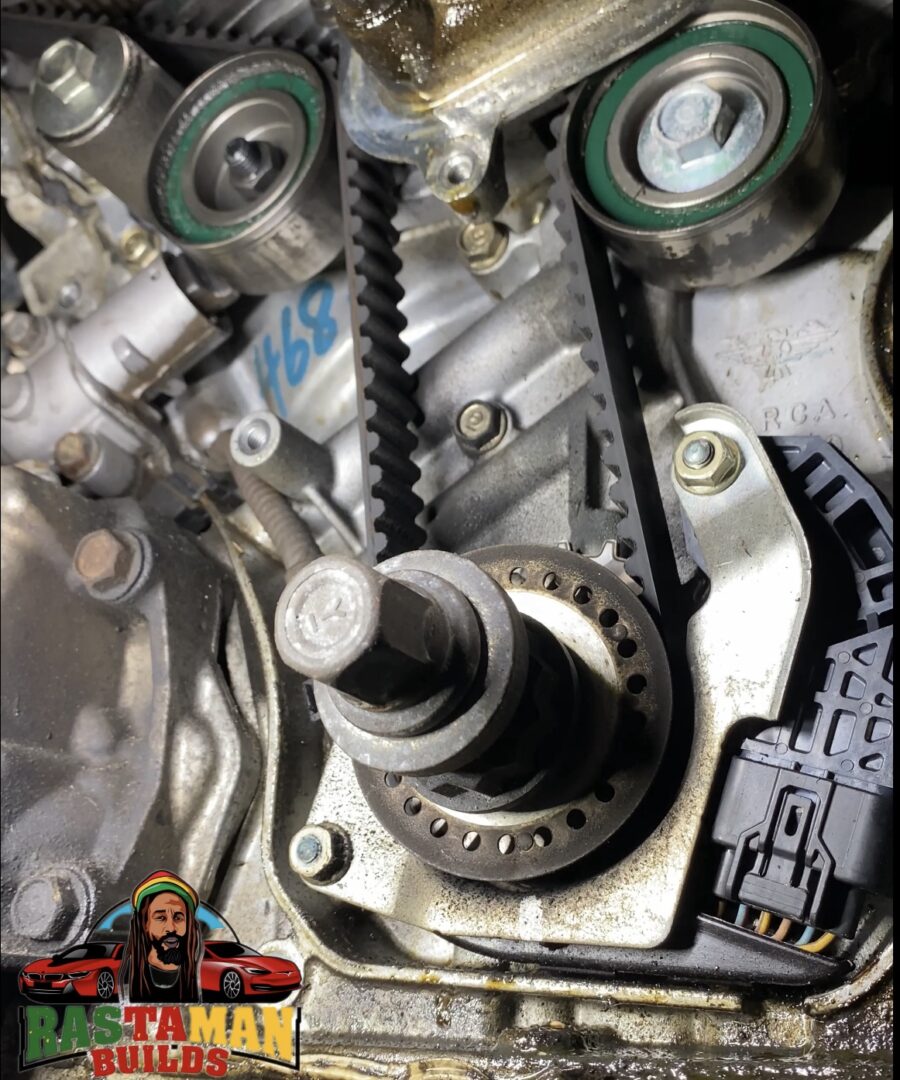

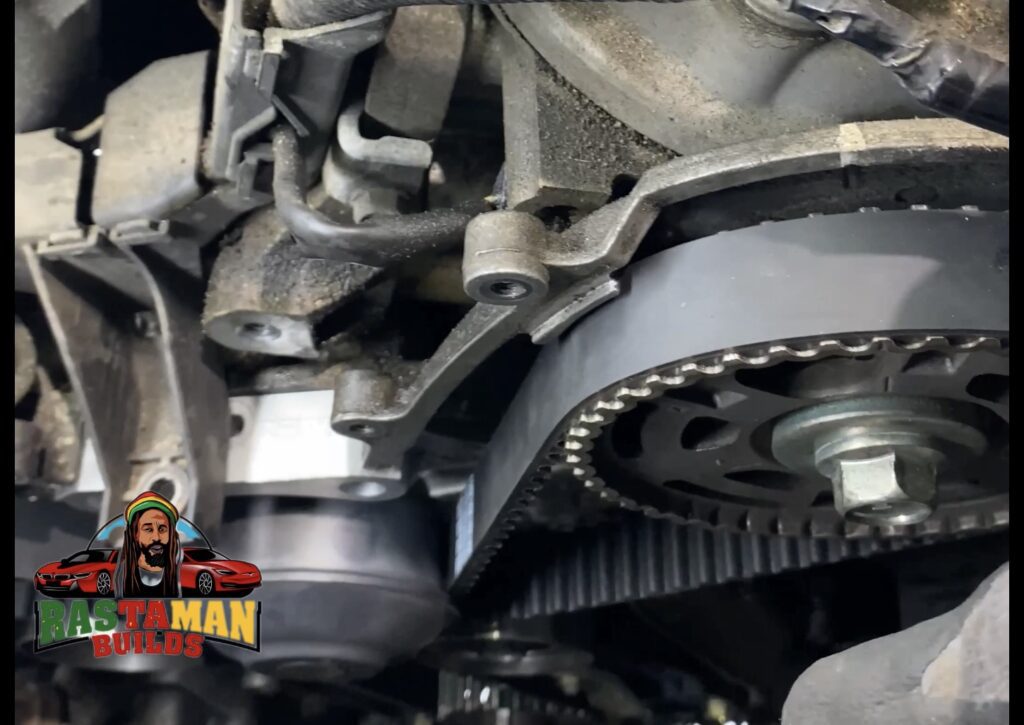

Timing belt jobs can be difficult when it’s time to get the belt over the gears, especially if it is a dual overhead four-cam engine. The belt will constantly fall off the gears as you install it—one little trick to help the belt stay on works well. I start at the crank pulley, then work clockwise or counterclockwise, depending on your engine but always end at the belt tensioner, and the tensioner will take up the remaining slack in the belt.

I use zip ties to hold the belt to the gears, preventing the belt from slipping off the gears as I work my way around all the pulleys and idlers. Just remember to remove them before you start the engine up.